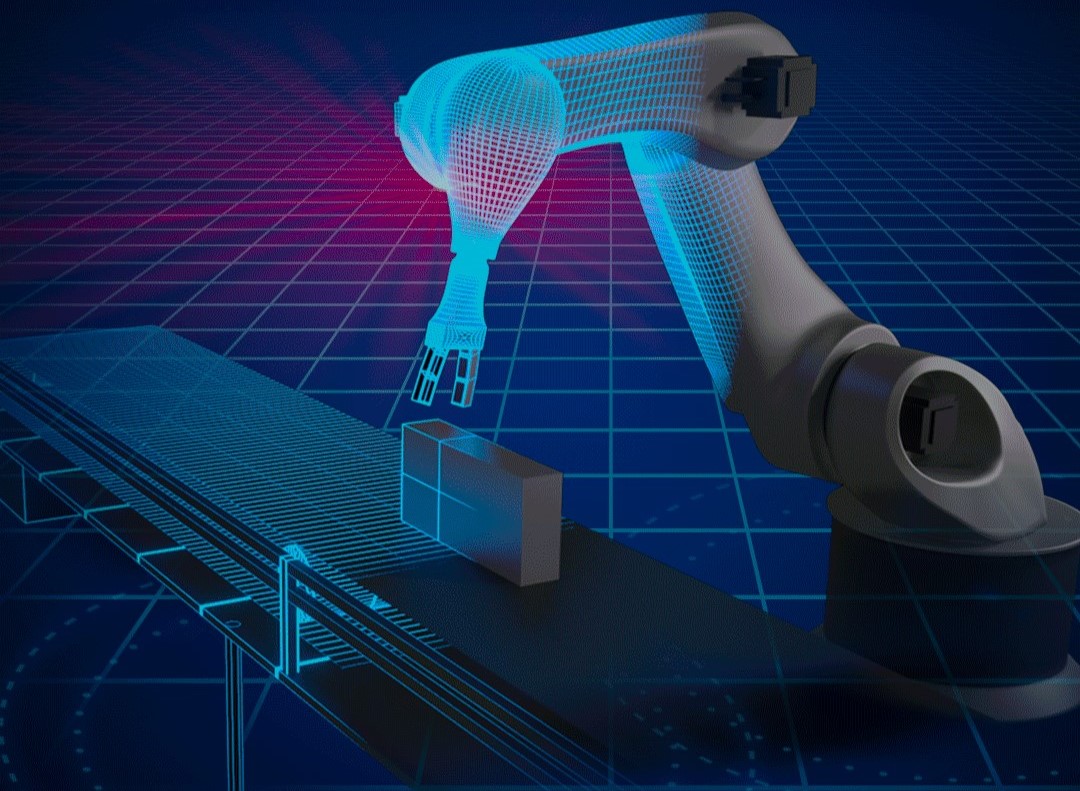

Optimising Manufacturing with Automation Machinery and LiDAR Technology

In an era where industries demand more efficiency and precision than ever before, automation machinery manufacturing has emerged as a game-changer. Businesses across a variety of sectors are leveraging this technology to streamline their operations and boost productivity.

At the heart of this transformation is LiDAR technology, a revolutionary tool that enhances automation processes and drives efficiency.

Automation Machinery Manufacturing: An Introduction

Automation machinery manufacturing refers to the design, development, and production of specialised equipment that automate tasks and processes across different industries. This technology-driven approach replaces manual labour with automated systems, with the aim of improving product quality and reducing cost.

Key components of automation machinery manufacturing include the design and engineering of automation systems, sourcing and assembly, programming and control, and rigorous QC testing and validation. These processes are designed to create manufacturing systems that can perform tasks autonomously, meeting industry standards and providing substantial efficiency gains.

LiDAR Technology: A Path to Efficiency

LiDAR, short for Light Detection and Ranging, is a remote sensing technology that uses laser pulses to measure distances and generate precise, high-resolution 3D maps of the surroundings. This technology is not new but has gained significant prominence in recent years, especially in the automation machinery manufacturing sector.

Here’s how LiDAR technology can play a pivotal role in improving processes within this industry:

1. Precision and Accuracy

The foremost advantage of LiDAR is its precision and accuracy. LiDAR sensors are capable of generating millions of data points per second, making it an ideal tool for capturing detailed information about the environment. In the context of automation machinery manufacturing, this data can be used to ensure that automated systems operate with optimal accuracy, reducing errors, process times and waste.

LiDAR can be integrated into automation machinery to scan and map the surroundings with sub-centimetre accuracy. This data can then be used to guide robots, drones, or other automated equipment, ensuring efficient path planning and task performance with maximum precision.

2. Enhanced Security

Security and protection are a top priority in any manufacturing environment. LiDAR technology can contribute by providing real-time monitoring and obstacle detection. Automated machinery equipped with LiDAR sensors can identify potential hazards in their path and make split-second decisions to avoid collisions, thus protecting machinery, personnel, and valuable components.

3. Improved Navigation

LiDAR technology helps mobile automation machinery perform accurate navigation and localisation. In warehouses and logistics centres, autonomous robots can utilise LiDAR to map their environment and determine their exact position in real-time. This enables efficient and optimised movement of goods, reducing process time and energy consumption.

4. Versatile Applications

LiDAR is a versatile tool that can be used in various sectors, from agriculture to manufacturing, construction, and material handling. For automation machinery manufacturing, this versatility means that LiDAR can be tailored to suit the specific needs of the process, allowing for customised solutions that cater to a wide range of needs.

5. Data-Driven Insights

LiDAR provides a massive amount of real-time data. The large datasets generated are invaluable for retrospective QC and incremental process improvement, facilitating performance analysis, identifying bottlenecks, optimising path planning, and enhancing machinery / system design. By leveraging these insights, it is possible to refine processes and achieve greater efficiency over time.

LiDAR in Action

To understand the full potential of LiDAR in automation machinery manufacturing, it is beneficial to explore some real-world examples where this technology has made a substantial impact:

1. Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robot (AMRs)

Warehouses and logistics centres are increasingly relying on AGVs and AMRs for material handling tasks. These vehicles can all make use of LiDAR sensors to navigate the complex environment of a warehouse, moving goods efficiently and safely. LiDAR technology enables AGVs/AMRs to adapt to dynamic changes in their surroundings, ensuring a smooth workflow.

2. Robotics in Manufacturing

Robotic arms equipped with LiDAR technology are finding applications in manufacturing processes that require high precision, such as assembling electronic components. The accuracy and real-time obstacle detection capabilities of LiDAR enable robots to work alongside humans, enhancing the overall efficiency of production lines.

3. Agricultural Automation

In agriculture, LiDAR technology is being used to optimise work practises. Autonomous tractors and drones use LiDAR sensors to assess crop health and apply pesticides or fertilisers with pinpoint accuracy. This not only improves crop yields but also increases productivity and reduces the use of costly agrochemicals, thereby, reducing environmental impact.

Implementing LiDAR in Your Business

If you are looking to enhance efficiencies within your business through LiDAR technology, there are some key steps to consider:

– Define Your Objectives: Clearly outline the specific areas in your automation machinery manufacturing process where LiDAR technology could make a difference.

– Select the Right LiDAR Solution: LiDAR technology comes in various forms. It is important to choose the form that best aligns with your business needs and budget.

– Integration and Testing: Collaborate with LiDAR technology experts to integrate the technology into your existing machinery / processes or develop custom solutions.

– Continuous Improvement: Use the data generated by LiDAR to identify areas for process improvement.

Conclusion

Automation machinery manufacturing and LiDAR technology are a powerful combination that can drive significant improvements in efficiency and productivity across various industries. With its precision and versatility implementation of LiDAR technology is a step toward a more efficient, safer, and cost-effective future.

We have a number of products that we would recommend for use in this area including the compact and versatile UST range from Hokuyo. You can find out more about this and our full selection of LiDAR scanners here. And make sure to stay up to date with all our news, insights and product developments by following us on LinkedIn and X.

Popular news

What is Art… and how can LiDAR technology be used to create it?

LiDAR has found new applications in interactive art installations, enabling impressive immersive experiences.

Read more

How does LiDAR compare to camera and RADAR technology?

Comparison of LiDAR (Light Detection and Ranging), Camera and RADAR (Radio Detection and Ranging) technology.

Read moreGet expert advice on which product is best for you:

Germany: +49 7824 70397-50

United Kingdom: +44 1666 660016

Get in touch